Electricity Arcs From Past to Present (or “Nichollas Builds a Wacky Desk Lamp”)

BY THE WAY, THIS IS THE ONE YEAR ANNIVERERY CHOLLA CONSPIRACY BLOG POST!

“Buy once, cry once” is a phrase I got from Jack Spirko of The Survival Podcast (https://tspaz.com) and I have taken it to heart. If I am going to buy a thing, such as a tool, hose, even socks, I would rather buy the best quality one I can afford, ideally lasting forever. I love Dark Tough (https://www.darntough.com) socks because they have a lifetime warranty. You can send them back with holes in them and they will fix/replace them for you. I have not actually sent any back yet but I do believe they will do what they say. The idea of coarse is less waste, better quality things, saving money in the long run, and remembering to appreciate how much technology has made our lives easier in many ways. So much so, that we have forgotten skills in a single generation that for so very long were considered common knowledge, many of them were essential to one’s survival.

American non-consumable possessions were once high quality manufactured products that were extremely functional and often life changing, but now what we have is easily accessible mountains of the lowest quality, mass produced products, including tons of things that offer absolutely zero practical value. I’m just as guilty as it as anyone, if not more, of buying into the cycle of purchasing things that I don’t need, getting things because they make me happy for a minute, and buying based on the lowest price when there is a long lasting option available. Lately, I’ve been seeing things differently though, and once you acknowledge one or two of the epiphanic elephants in the room, it can start an avalanche and one may find themselves going down one rabbit hole after another.

We were not given the tools necessary to understand some of the most influential aspects of life, such as something as ubiquitous as money. Like, what exactly is money/currency, where does it come from and how does it work? There are so many complicated technologies out there that only a handful of people truly understand, but something as basic as “what is money” and “how does it work” should be taught to everyone. We spend the majority of our lives focused on the acquisition and transfer of money, yet how many people were taught about fractional reserve banking during mandatory schooling?

It sounds complicated, surely on purpose, but it is extremely simple. Basically, people used to keep their gold at the goldsmith’s when it was used as money(currency), which was only natural. So the goldsmith would write out a slip indicating how much gold they were keeping for a person. This acted kinda like paper money, except it was actually a record of how much gold was being held for them(at least that was the idea right). Well the keepers of the gold realized after a while that they never needed to use more than 10% or 20% of their holdings (somewhere around there) and realized that they could use a certain (high) fraction of the gold which was owned by other people and use it for their own purposes. When they did that, they increased the number of paper slips or otherwise used gold in two forms of value at the same time, and this is how a fractional reserve system literally produces money out of thin air.

That is just a simple story, and whether it is true or not, it does a good job of demonstrating how and why it works when it does. They only keep a fraction at a time on reserve. For example, a 100,000$ deposit which had a 10% reserve requirement would require the bank to have 10,000$ “on hand”. Then the other 90,000$ could be loaned to another person, adding to the money supply. This is not exactly how it works today, some companies are not required to have any reserves, which is confusing to me.

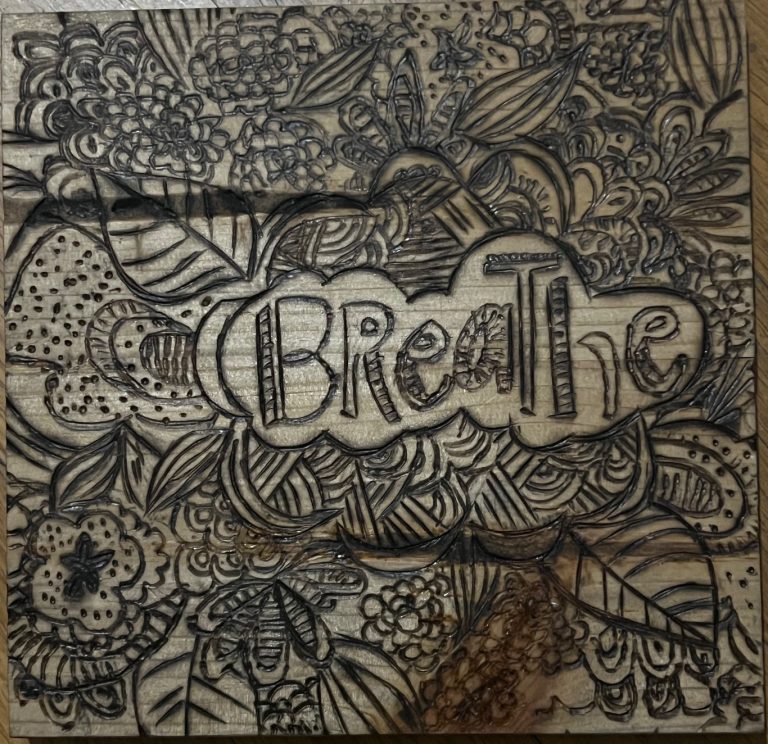

Lately, my wife and I have been trying to find a way to build things we need and repair things that break rather than buy a cheap replacement from Amazon or Walmart. For example, my wife needed a good light for her desk, and at first we took a look at Amazon. They had many, too many different options, plenty of which might work fine, but they were mostly plastic and not made to last or to be repaired. So I decided to build one myself.

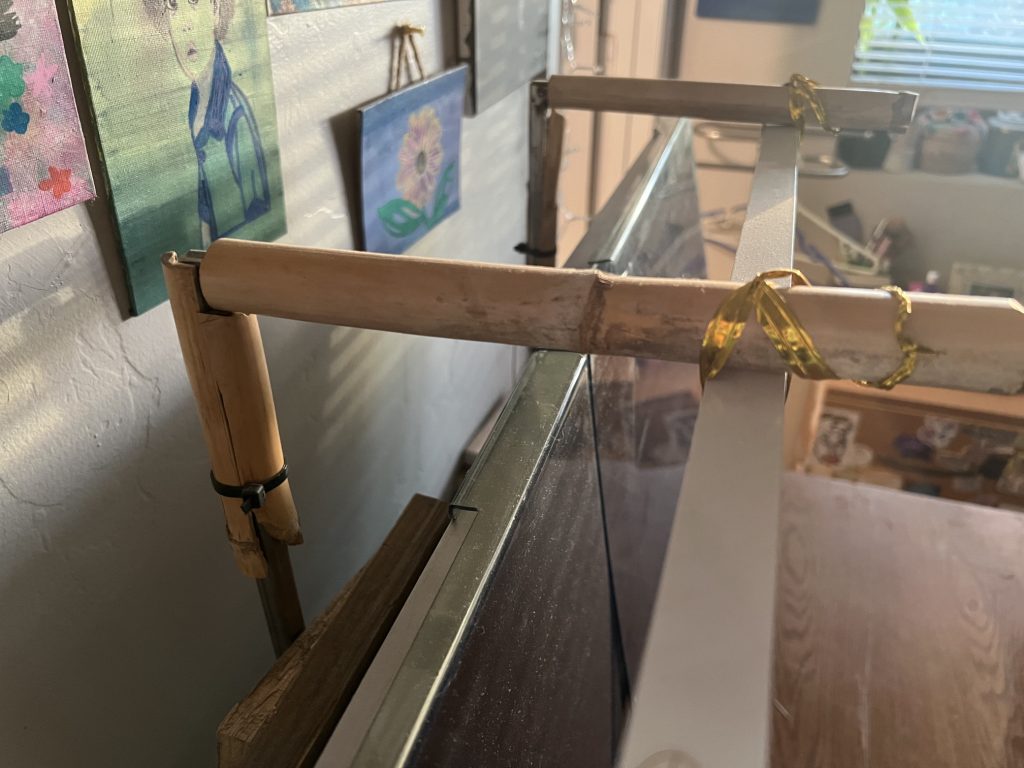

To be clear, I was just planning on suspending an LED bar over her desk in front of her two screens, but it needed a frame to hold it up and out over the monitor since Abril didn’t like my original idea of hanging it from the ceiling, lol. I originally was just going to use bamboo, but I couldn’t figure out how to connect two pieces at 90 degrees and be able to hold up the light, although I’m sure there’s plenty of ways to do that. I had some scrap metal bars for welding practice, so I came up with the idea of a metal frame surrounded by bamboo, and I would get to practice with a little flux welder I got ahold of not too long ago.

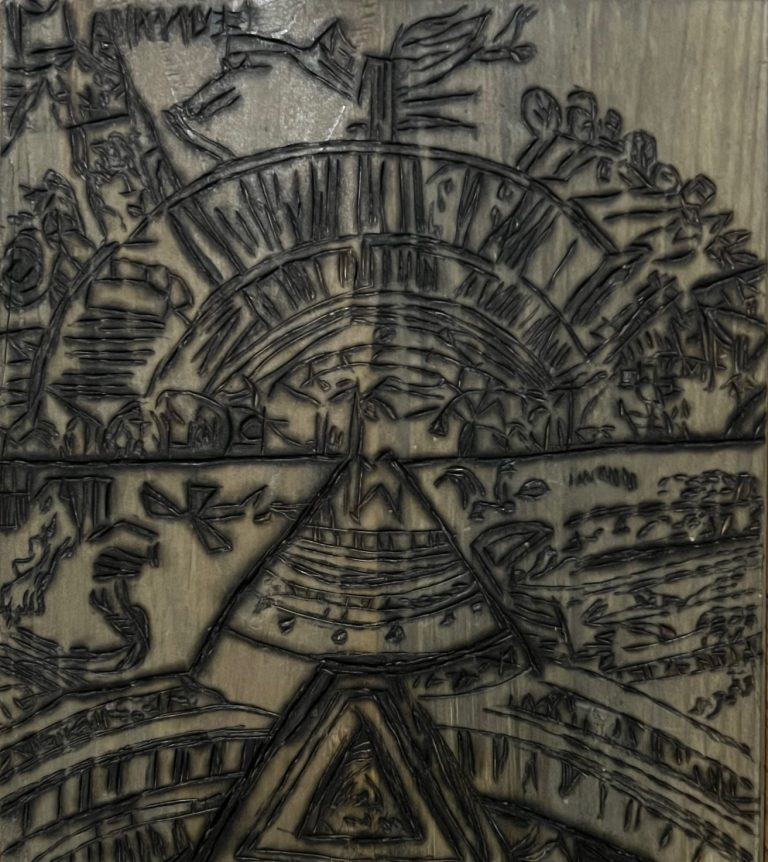

Going back quite a few years to a previous life… I first started welding in Seattle, WA, when I was working at a boat fabrication shop. My job was to sweep… just sweep. They made boats for cleaning oil spills, whale watching, the police,… also the Coast Guard, etc. The huge shop felt always felt like an alien world, as I shuffled around in what felt like a space suit: my stained jumpsuit, boots, gloves, respirator, and eye protection. I would just wander all around, up and down, inside and out of the giant metal sea creatures as they come to life bit by bit. Somehow the lighting kind of even made it feel like some sort of robot womb: showers of sparks flying randomly from any direction, and the sounds of buzzing, hissing, and grinding seal out any other sensory connection to the outside world; even my loudest screams, or singing, cannot make the trip from inside my head and back to my ears. I spend half my time moving piles of tiny shiny aluminum curlies around and the other half exploring this amusement park of molten metal, shaped by tools they call “man eaters” and such.

Socially, this was very different for me as well. I had never worked anywhere like this, and the “blue collar” culture was very difficult to cope with. People were not friendly, and on the first day one guy kept acting like he wanted to fight. Two of my aunts worked blue collar jobs, and growing up I would sometimes be around the people they worked with and had been to the shop before, so it felt familiar, but I was not made to feel welcome in any way. It didn’t help that I stuck out, as I was the only one who wore a respirator (alumium dust and all sorts of chemicals and gases fill the air, but since we all smoked cigarettes, they thought it was hypocritical of me to wear a respirator while working), and I just did not fit in with them in general, but I was plenty used to being the laughed-at-loner, so I just stuck it out, and eventually everyone became friendly with me.

Of all the ridiculous and dangerous things I did while on the clock at that job, eventually it all became about welding. One of the guys showed me the basics, and I loved it. The welder, cutting tools, and grinders were so much fun. I ended up practicing quite a bit and passed the welding exam by building a box to their specifications with solid, beautiful welds that looked like stacks of dimes that had fallen on their side and proper corner welds. If you’ve looked at an aluminum weld before, you probably have an idea of what I mean as far as the dimes. I loved it and thought the science behind it was so interesting, and the act was beautiful and powerful. But I didn’t really care about it as a path to a better job; I just loved the process and learning the skill. I could have gotten a job there as a welder, but the next chapter of my life began instead… whatever chapter that was.

This really was the type of company that was more common in my mom and aunt’s generation (70’s and 80’s, I guess?). It was a family company, and they really seemed to care about their employees. It was hard work, but they paid well, and I believe they provided benefits for their workers, or one way or another things were different. This was a lot like the company I was working for, and they would trust us and treat us very respectfully. Unfortunately, they were too trusting, because back then if you gave me an inch, I would take a mile, especially when it came to work. I didn’t look at it as the opportunity that other people saw it as, and I ended up spending most of my time doing things other than sweeping. I was just there to get a paycheck, and as long as I still got that check, I would essentially do as I please. They could never tell if things were being cleaned up anyways because it was constantly covered in metal shavings.

Now, it’s many years later, and I’m discovering that I want to learn to do everything myself, which quickly led me back to welding.

This was my first project on my own with my flux welder (welding without a gas to protect it so instead there are some kind of chemicals or something in the wire that do the job that a tank of gas would usually do). In short, I took 5 pieces of steel bars and cut them to the sizes I needed. I used a marble table I found to do the welding, and one at a time got them fused together, although they were extremely ugly. Flux welding is uglier anyways until you clean it up, but these welds were terrible looking. However, when I pulled strongly on them, they flexed and did not crack, so I cleaned them up and left them.

The last weld gave me problems. Maybe because when I would pull on it, I had the greatest leverage at that point so it put more strain on the weld. It also allowed me to practice. I fiddled with the two basic settings: wire speed and power (high or low). I tried different thicknesses of wire and different distances from the tip of the gun to the metal. After 4 or 6 tries, I had figured out how each variable, among others, affects the weld, and by my last weld, I was 100% certain that I had fully fused the two bars into one solid piece. I took off my mask while it was still hot, and it glowed so intensly and for quite a little while. I sat and stared at it and smiled, because it was beautiful.